Service Offerings

From the initial sketch to the tested prototype ready for serial production. All under one roof.

Technical Development

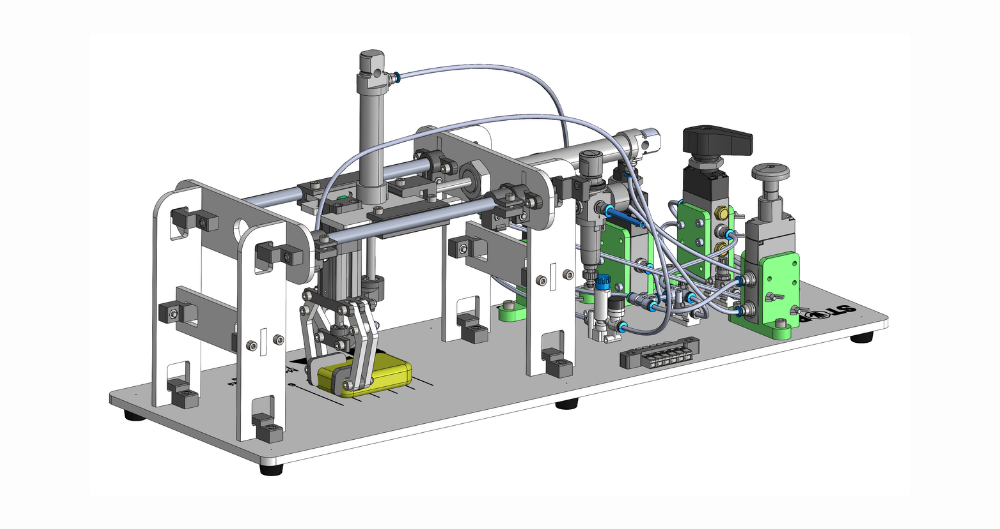

We specialise in comprehensive technical development and engineering in the fields of mechanical engineering and technical design. Capable of designing and creating individual machine components or complete devices from scratch. With a deep understanding of mechanics and electronics, we can devise innovative operational principles, enabling our clients to achieve optimal performance and efficiency. Our hallmark is the ability to provide technical solutions with an emphasis on precision, quality, and reliability, which is the cornerstone of our success in the field of engineering. We offer development capacities for the technical advancement of your device or product.

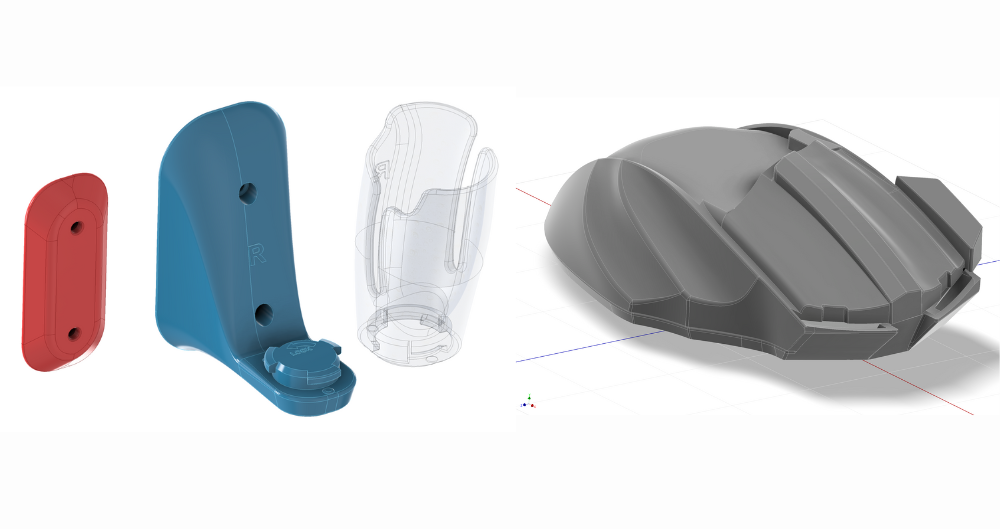

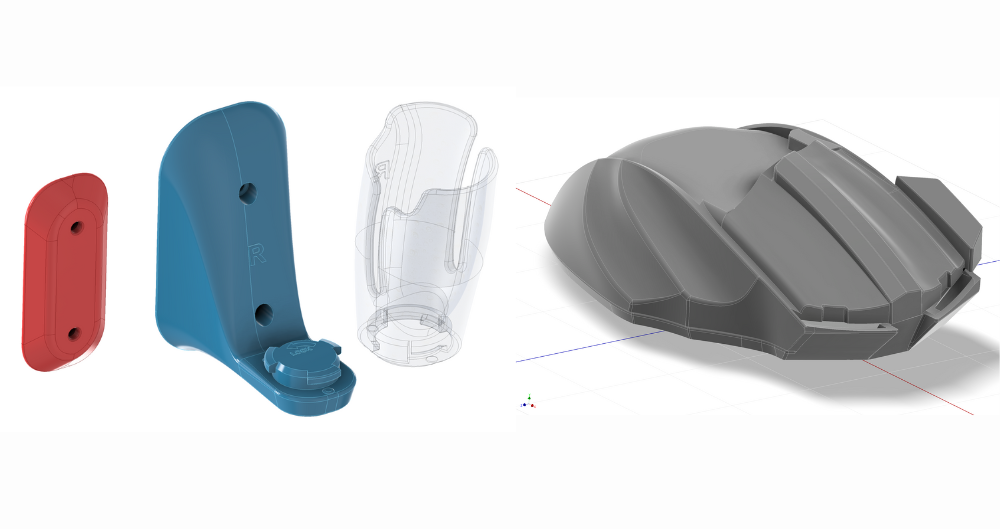

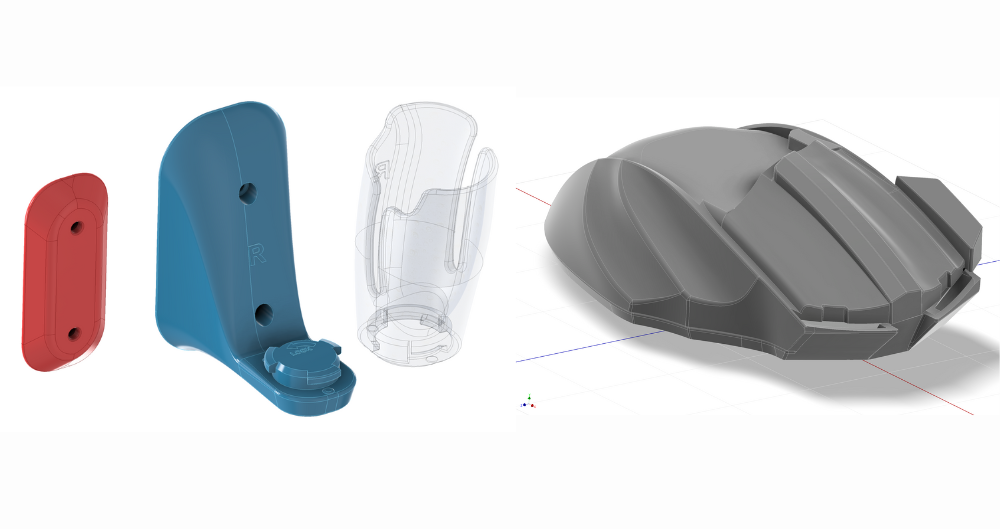

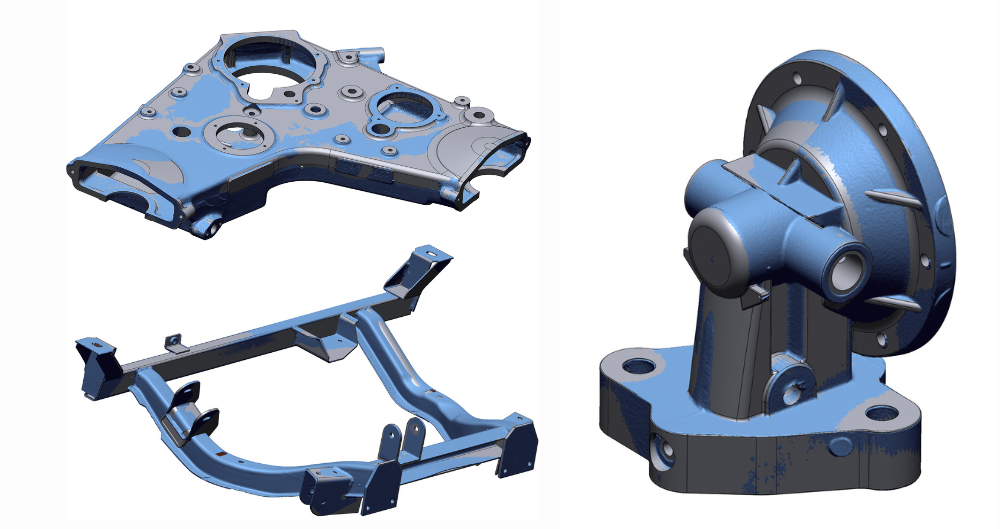

3D Modelling

Our domain is 3D modeling and CAD design, utilizing professional CAD software. We offer a wide range of custom modeling services to meet the individual needs of our clients. We provide services ranging from comprehensive parametric modeling to advanced free-form modeling and organic shapes, as well as handling small requests for quick, simple models. Our experience in CAD design enables us to undertake diverse projects and ensure precision and quality in every created model.

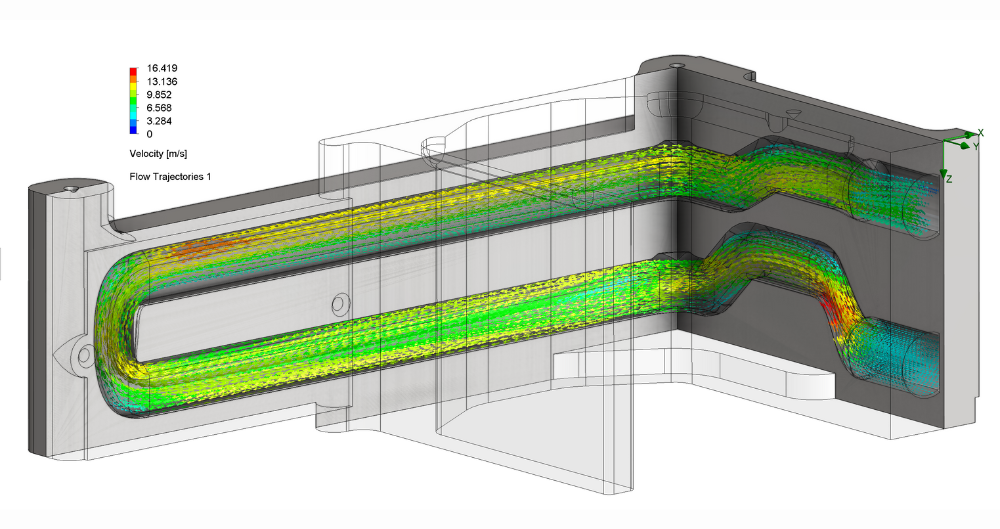

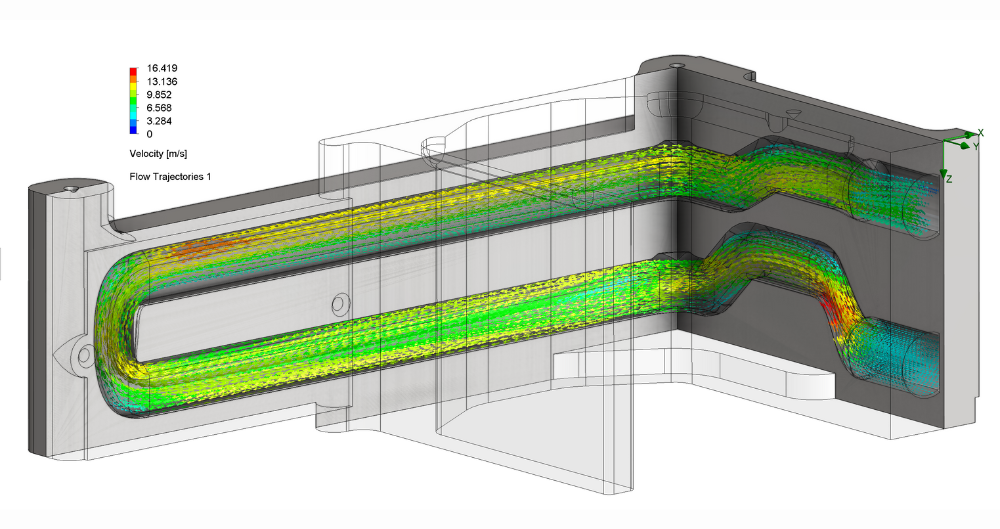

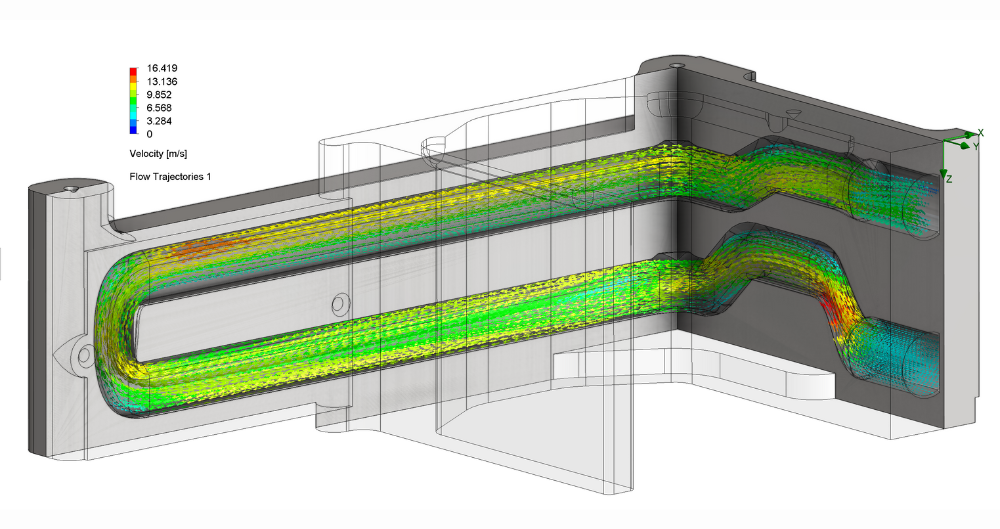

Calculations and Analysis

As part of technical design, we excel in handling various types of calculations. Whether it's complex stress analyses, overall gear calculations, or routine technical calculations, we can accommodate them all in the design process and create solutions precisely according to the requirements.

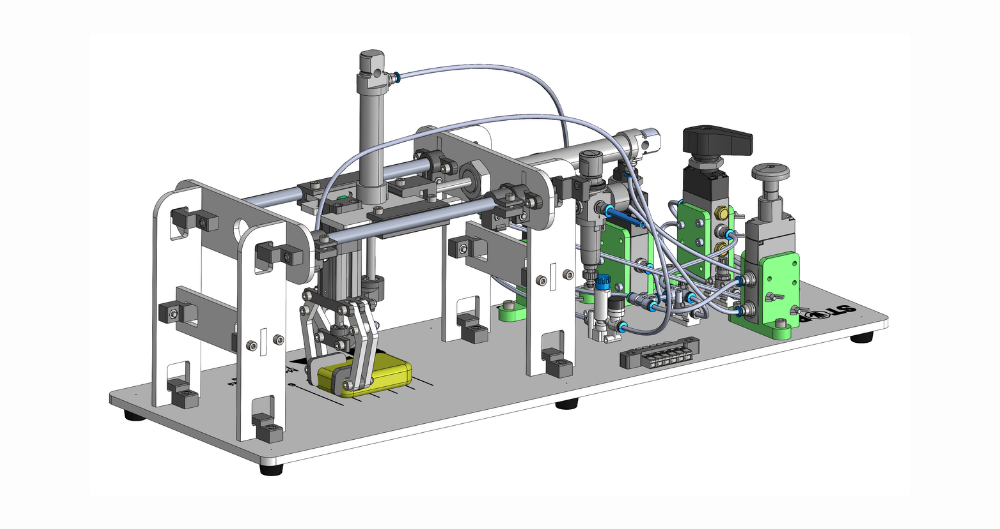

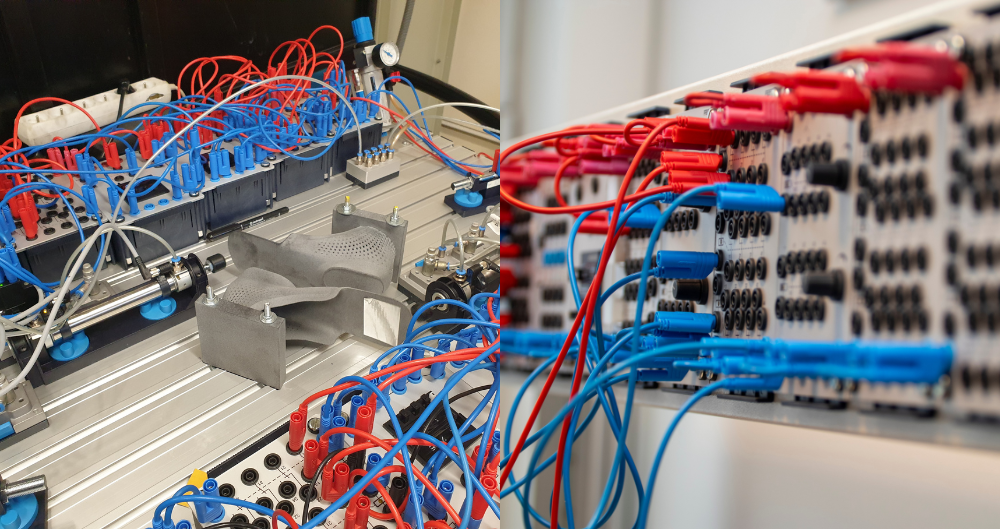

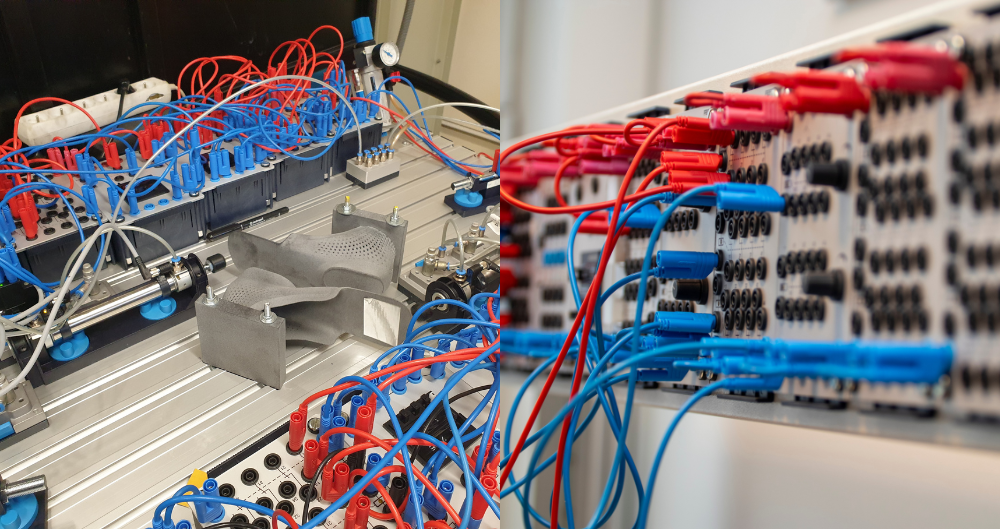

Testing

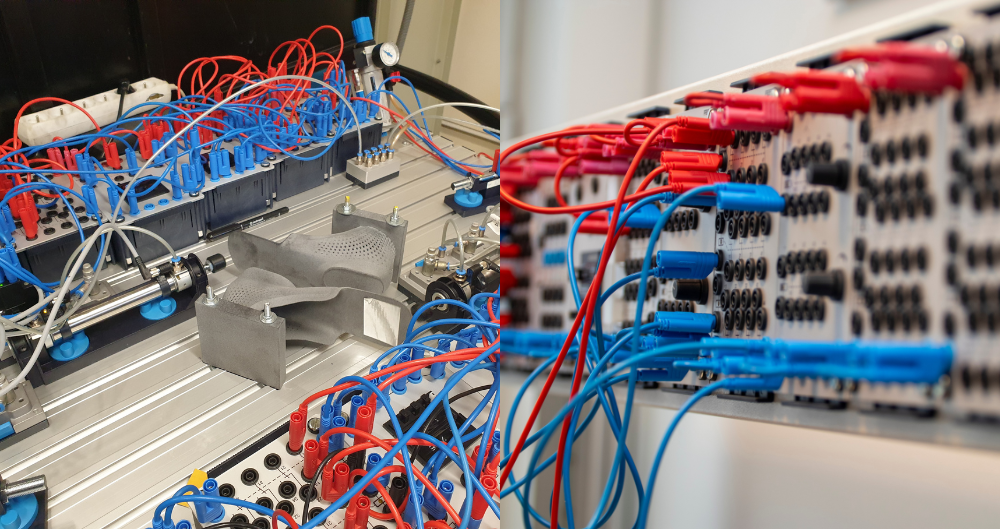

Thanks to our equipment, we can not only design and manufacture proposed devices but also test them. We have testing stands equipped with electronics and pneumatics, a wide range of sensors, and controls. We can conduct short-term and long-term testing and are capable of designing permanent equipment monitoring and cloud data collection.

Custom Manufacturing and Prototyping

Thanks to our equipment, we can not only design and manufacture proposed devices but also test them. We have testing stands equipped with electronics and pneumatics, a wide range of sensors, and controls. We can conduct short-term and long-term testing and are capable of designing permanent equipment monitoring and cloud data collection.

3D Printing

We offer custom 3D printing services. This technology is extensively used in most of our prototyping, and we have several professional and hobby-grade printers in our arsenal. We can handle the printing process itself, as well as prepare printing data and design parts suitable for additive manufacturing technology. Our expertise lies in filament-based FDM and powder-based SLS printing using various polymer types. Additionally, we can facilitate SLM metal printing, whether it's aluminum alloy, stainless steel, or titanium.

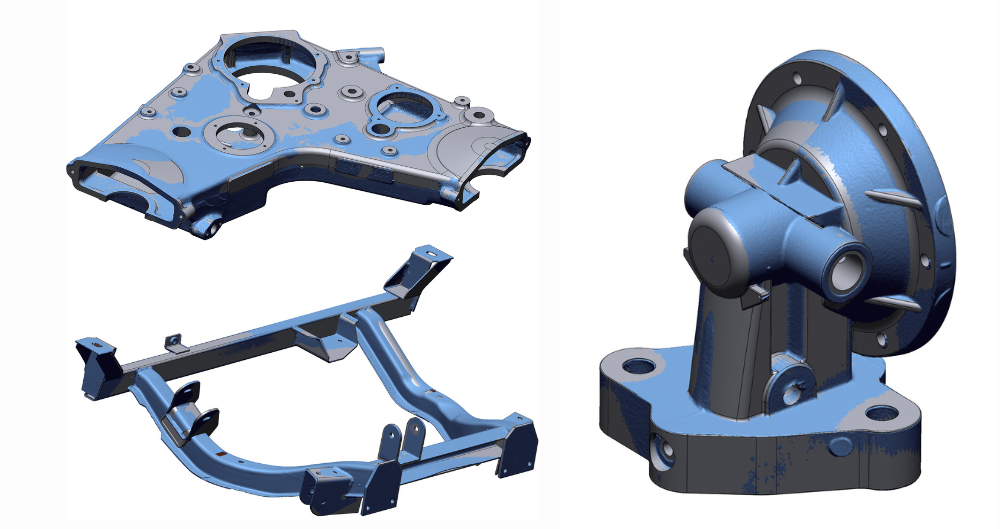

Reverse Engineering

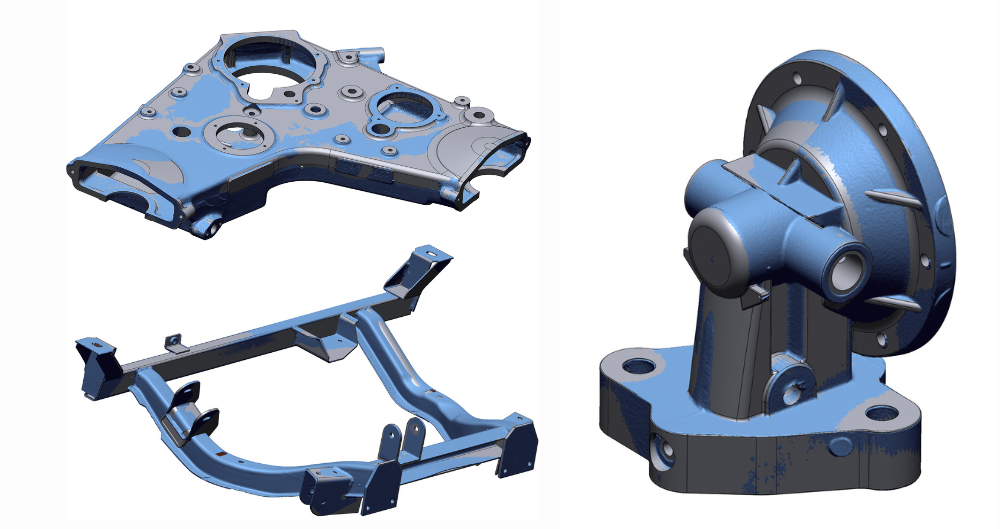

We offer comprehensive reverse engineering services, which involve converting a physical part into a digital model. Typically, we scan the part using a 3D scanner and then create an accurate model based on this data. We can handle broken originals, missing parts, or wear and tear on the prototype. The model can be adjusted and any weaknesses can be addressed, or it can be modified as needed. The result is a volumetric model based on the prototype, which can be further used in CAD environments or processed or even printed. This approach is ideal for parts that are no longer available, lack documentation, or are no longer in production.

Laser Cutting and Engraving

We have large-format laser cutting and engraving capabilities. We can cut plywood, plastics, leather, etc., up to a size of 1600x900mm. Our engraving laser can precisely engrave metals with perfect detail. We can quickly produce cutouts for your project, engrave supplied parts, or efficiently create device structures from cutouts for prototyping and testing purposes.

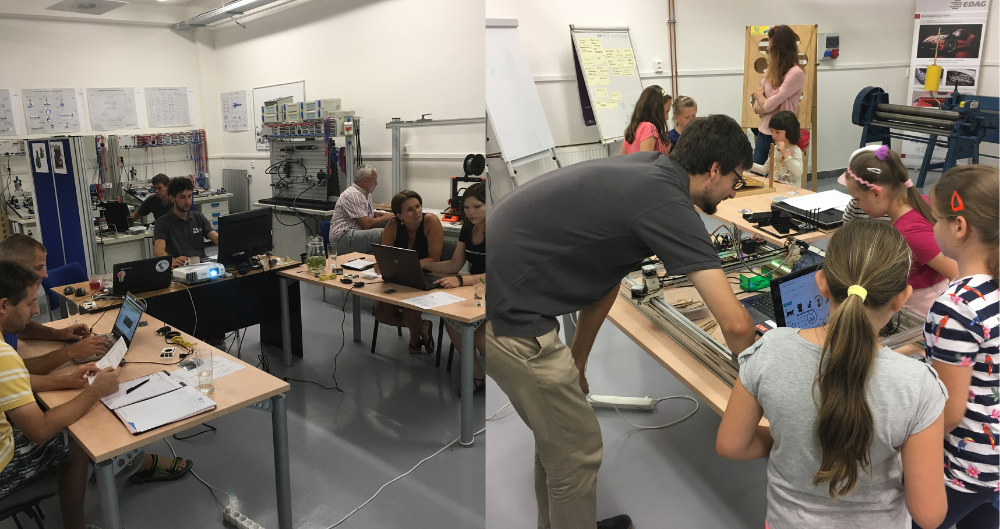

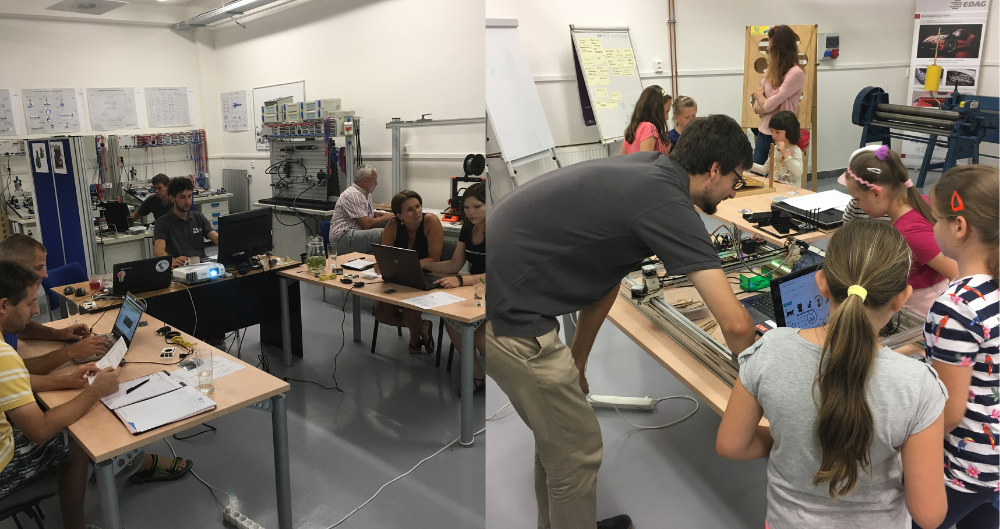

Training

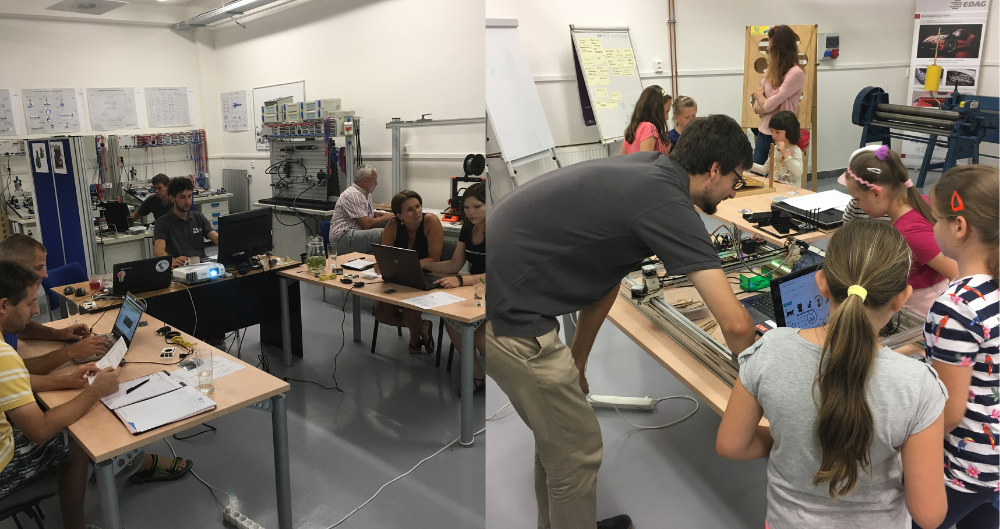

We excel in technical expertise and are adept at passing on this knowledge. Whether you're interested in deepening your knowledge in one of our areas of expertise or creating tailored training to meet your needs, we're here to help. We participate in delivering professional technical training for companies, courses for hobbyists, and we also have experience with summer camps and technical retreats.

We specialise in comprehensive technical development and engineering in the fields of mechanical engineering and technical design. Capable of designing and creating individual machine components or complete devices from scratch. With a deep understanding of mechanics and electronics, we can devise innovative operational principles, enabling our clients to achieve optimal performance and efficiency. Our hallmark is the ability to provide technical solutions with an emphasis on precision, quality, and reliability, which is the cornerstone of our success in the field of engineering. We offer development capacities for the technical advancement of your device or product.

Our domain is 3D modeling and CAD design, utilising professional CAD software. We offer a wide range of custom modeling services to meet the individual needs of our clients. We provide services ranging from comprehensive parametric modeling to advanced free-form modeling and organic shapes, as well as handling small requests for quick, simple models. Our experience in CAD design enables us to undertake diverse projects and ensure precision and quality in every created model.

As part of technical design, we excel in handling various types of calculations. Whether it’s complex stress analyses, overall gear calculations, or routine technical calculations, we can accommodate them all in the design process and create solutions precisely according to the requirements.

Thanks to our equipment, we can not only design and manufacture proposed devices but also test them. We have testing stands equipped with electronics and pneumatics, a wide range of sensors, and controls. We can conduct short-term and long-term testing and are capable of designing permanent equipment monitoring and cloud data collection.

We specialise in custom prototyping and manufacturing of technical parts tailored to the customer’s requirements. Using our equipment, we can rapidly and efficiently produce parts for your project or even realise and construct the entire project. Whether it’s laser cutting of plywood or 3D printed parts for your project, manufacturing prices or medals for your event, or you need to produce and engrave items for your exhibition, we can manufacture components quickly and accurately according to your needs.

We offer custom 3D printing services. This technology is extensively used in most of our prototyping, and we have several professional and hobby-grade printers in our arsenal. We can handle the printing process itself, as well as prepare printing data and design parts suitable for additive manufacturing technology. Our expertise lies in filament-based FDM and powder-based SLS printing using various polymer types. Additionally, we can facilitate SLM metal printing, whether it’s aluminum alloy, stainless steel, or titanium.

We offer comprehensive reverse engineering services, which involve converting a physical part into a digital model. Typically, we scan the part using a 3D scanner and then create an accurate model based on this data. We can handle broken originals, missing parts, or wear and tear on the prototype. The model can be adjusted and any weaknesses can be addressed, or it can be modified as needed. The result is a volumetric model based on the prototype, which can be further used in CAD environments or processed or even printed. This approach is ideal for parts that are no longer available, lack documentation, or are no longer in production.

We have large-format laser cutting and engraving capabilities. We can cut plywood, plastics, leather, etc., up to a size of 1600x900mm. Our engraving laser can precisely engrave metals with perfect detail. We can quickly produce cutouts for your project, engrave supplied parts, or efficiently create device structures from cutouts for prototyping and testing purposes.

We excel in technical expertise and are adept at passing on this knowledge. Whether you’re interested in deepening your knowledge in one of our areas of expertise or creating tailored training to meet your needs, we’re here to help. We participate in delivering professional technical training for companies, courses for hobbyists, and we also have experience with summer camps and technical retreats.

-

Technical Development

-

3D Modelling

-

Calculations and Analysis

-

Testing

-

Custom Manufacturing and Prototyping

-

3D Printing

-

Reverse Engineering

-

Laser Cutting and Engraving

-

Training

Technical Development

We specialise in comprehensive technical development and engineering in the fields of mechanical engineering and technical design. Capable of designing and creating individual machine components or complete devices from scratch. With a deep understanding of mechanics and electronics, we can devise innovative operational principles, enabling our clients to achieve optimal performance and efficiency. Our hallmark is the ability to provide technical solutions with an emphasis on precision, quality, and reliability, which is the cornerstone of our success in the field of engineering. We offer development capacities for the technical advancement of your device or product.

3D Modelling

Our domain is 3D modeling and CAD design, utilising professional CAD software. We offer a wide range of custom modeling services to meet the individual needs of our clients. We provide services ranging from comprehensive parametric modeling to advanced free-form modeling and organic shapes, as well as handling small requests for quick, simple models. Our experience in CAD design enables us to undertake diverse projects and ensure precision and quality in every created model.

Calculations and Analysis

As part of technical design, we excel in handling various types of calculations. Whether it’s complex stress analyses, overall gear calculations, or routine technical calculations, we can accommodate them all in the design process and create solutions precisely according to the requirements.

Testing

Thanks to our equipment, we can not only design and manufacture proposed devices but also test them. We have testing stands equipped with electronics and pneumatics, a wide range of sensors, and controls. We can conduct short-term and long-term testing and are capable of designing permanent equipment monitoring and cloud data collection.

Custom Manufacturing and Prototyping

Thanks to our equipment, we can not only design and manufacture proposed devices but also test them. We have testing stands equipped with electronics and pneumatics, a wide range of sensors, and controls. We can conduct short-term and long-term testing and are capable of designing permanent equipment monitoring and cloud data collection.

3D Printing

We offer custom 3D printing services. This technology is extensively used in most of our prototyping, and we have several professional and hobby-grade printers in our arsenal. We can handle the printing process itself, as well as prepare printing data and design parts suitable for additive manufacturing technology. Our expertise lies in filament-based FDM and powder-based SLS printing using various polymer types. Additionally, we can facilitate SLM metal printing, whether it’s aluminum alloy, stainless steel, or titanium.

Reverse Engineering

We offer comprehensive reverse engineering services, which involve converting a physical part into a digital model. Typically, we scan the part using a 3D scanner and then create an accurate model based on this data. We can handle broken originals, missing parts, or wear and tear on the prototype. The model can be adjusted and any weaknesses can be addressed, or it can be modified as needed. The result is a volumetric model based on the prototype, which can be further used in CAD environments or processed or even printed. This approach is ideal for parts that are no longer available, lack documentation, or are no longer in production.

Laser Cutting and Engraving

We have large-format laser cutting and engraving capabilities. We can cut plywood, plastics, leather, etc., up to a size of 1600x900mm. Our engraving laser can precisely engrave metals with perfect detail. We can quickly produce cutouts for your project, engrave supplied parts, or efficiently create device structures from cutouts for prototyping and testing purposes.

Training

We excel in technical expertise and are adept at passing on this knowledge. Whether you’re interested in deepening your knowledge in one of our areas of expertise or creating tailored training to meet your needs, we’re here to help. We participate in delivering professional technical training for companies, courses for hobbyists, and we also have experience with summer camps and technical retreats.